线缆表面缺陷检

线缆表面缺陷CCD检测系统

CCD detection system for surface defects of wire cable

生产线缆还靠人工手摸吗? 质量控制还在靠人工手摸盲测吗?

虽然很努力了,还是人为因素不能避免,缺陷依然检测不出来?客户依然投诉?员工管理依然很难,复检依然费时费力?

怎么办?怎么办?怎么办?

快来咨询我们吧!

我们能为您带来什么价值?

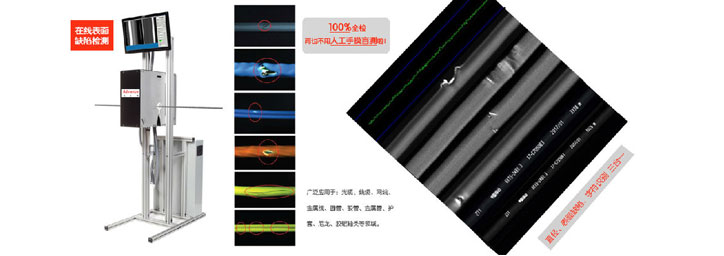

人工智能取得了全新的技术突破,为您的线缆质量管理体系做整体解决方案!直径测量、表面缺陷、字符检测一举三得!可视化、提前预警、去人工全检!

样品I/Sample

要求II/requirements

2.1线缆表面缺陷检测:

Detection for surface defects of wire cable

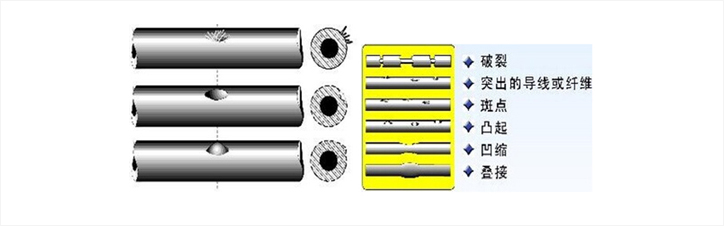

1、脱料划伤破裂突出的皮层斑点凸起凹陷叠接等缺陷,

Stripping, scratching and rupturing, protrudent skin layer, bulging spot, recession, overlapping, etc.

2、线缆变细,变粗等,

Wire cable thins or thickens, etc.

3、灵敏度参数可调

Adjustable sensitivity parameter

2.2、字符印刷质量检测

Detecting of letter quality of characters

1、线缆表面字符印刷质量检测

Detecting of letter quality of characters on surface of wire cable

2、对线缆长度数字的字符识别,并能自动累加数学计算

Character recognition for the digits of wire cable length, and can automatically accumulate mathematical computation

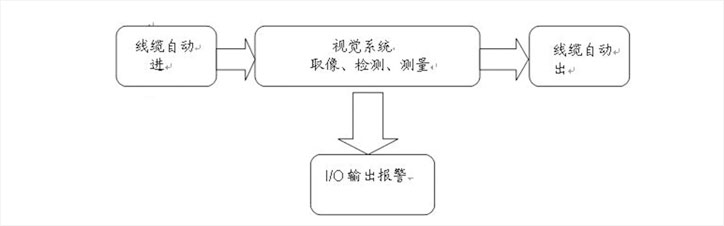

检测步骤III/Detecting steps

3.1.系统原理

System theory

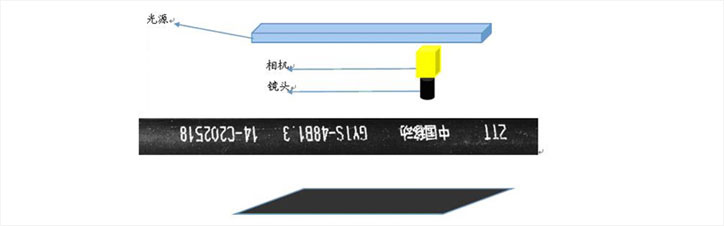

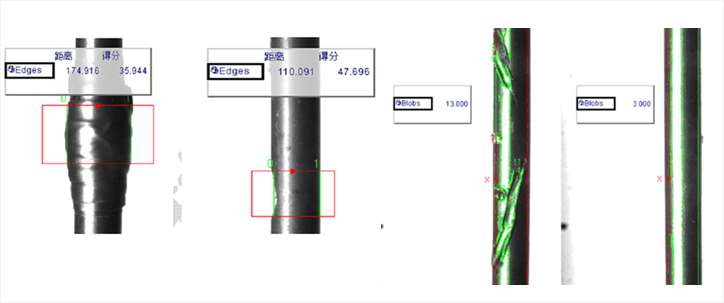

3.2.实验图

Experiment figure

检测结果IV/Detection result

线缆表面缺陷检测是采用3条互成120度的视觉投影,可以无盲区的检测到产品的细小缺陷,即使缺陷很小而且高速也能检测到;线缆字符印刷质量检测是通过视频分析OCR字符识别来实现;同时具有系统软件管理与数据分析功能。

Adopting three visual projections which form 120 degrees between each other, detection of surface defects of wire cable can detect products' fine defects without dead zones, even the very small and rapidly moving ones. The detecting of letter quality of wire cable characters is realized via analysis on OCR character recognition on video, also is provided with system software management and data analysis.

4.1线缆表面缺陷检测

Detection for surface defects of wire cable

(1)、脱料划伤破裂突出的皮层斑点凸起凹陷叠接等缺陷,

Stripping, scratching and rupturing, protrudent skin layer, bulging spot, recession, overlapping, etc.

(2)、线缆变细,变粗等,

Wire cable thins or thickens, etc.

(3)、灵敏度参数可调

Adjustable sensitivity parameter

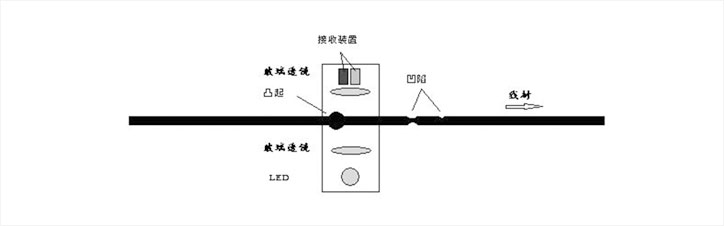

a.以下示意图表示了测量设备在一个轴向上的结构, 这种结构可以有效保证测量结果的准确性

Following schematic diagram shows the structure of measurement equipment in one axial direction. This structure can efficiently guarantee accuracy of measurement result.

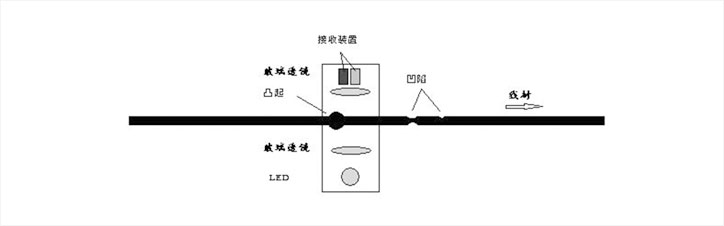

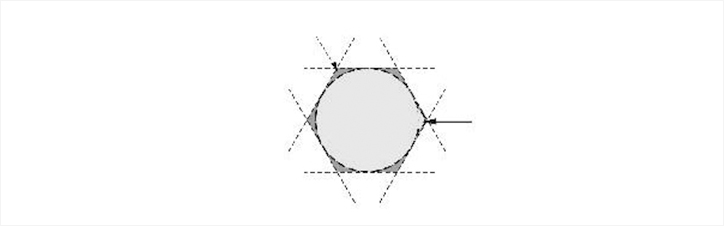

b.以下示意图表示了测量设备在三个轴向上的结构采用三个维度的检测结构, 这种结构可以有效保证测量结果的准确性。

Following schematic diagram shows the structure of measurement equipment in three axial directions. This detection structure of three dimensions can efficiently guarantee accuracy of measurement result.

在电线线缆的外观缺陷检测中,采用3条互成120度,可以无盲区的检测到产品的细小缺陷,即使缺陷小而且高速也能检测到。

In detection of appearance defects for wire cable, three visual projects which form 120 degrees between each other are adopted to detect the find defects of products, even very small and rapidly moving ones.

c.以下示意图表示了测量设备的检测特征对于产品的特征缺陷特征,特别是缺陷较小不是非常明显是,基本能实现”零缺陷”,可以有效保证产品质量的准确性和精确度.

Following schematic diagram shows detection features of measurement equipment. "Zero defects" can basically be realized to effectively guarantee products’ accuracy and precision especially when the defects are very small and insignificant.

d.测量设备的技术参数

Technical parameters of measurement equipment

检测方向:3

Detection direction:3

检测方式:非接触式连续测量

Detection mode: non-contact continuous measurement

警报输出:红色LED亮,报警常开接点闭合

Alarm output: when red LED is on, normally open contact of alarm is closed

报警时间:0.1sAlarm time: 0.1s

使用温度:-5℃- +55℃

Service temperature:- 5℃- +55℃

功耗:10~200W

Power consumption: 10-200w

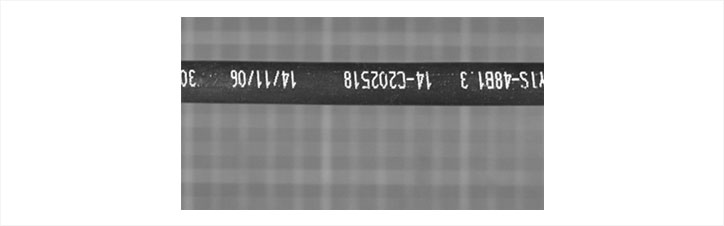

4.2字符印刷质量检测

Detection of letter quality of characters

(1)、线缆表面字符印刷质量检测

Detection of letter quality of characters on surface of wire cable

(2)、对线缆长度数字的字符识别,并能自动累加数学计算

Character recognition for the digits of wire cable length, and can automatically accumulate mathematical computation

a以下示意图表示了字符质量检测系统结果图

Following schematic diagram shows result of character quality detection system

b 测量设备的技术参数

Technical parameters of measurement equipment

检测方式:光学非接触式连续测量

Detection mode: optical non-contact continuous measurement

检测方向角:线缆字符旋转角度范围30度

Detection azimuth: scope of character rotation angles of wire cable is 30 degrees

警报输出:红色LED亮,报警常开接点闭合,数据输出

Alarm output: when red LED is on, normally open contact of alarm is closed, and data is outputted

报警时间:0.1s

Alarm time: 0.1s

使用温度:-5℃- +55℃

Service temperature:- 5℃- +55℃

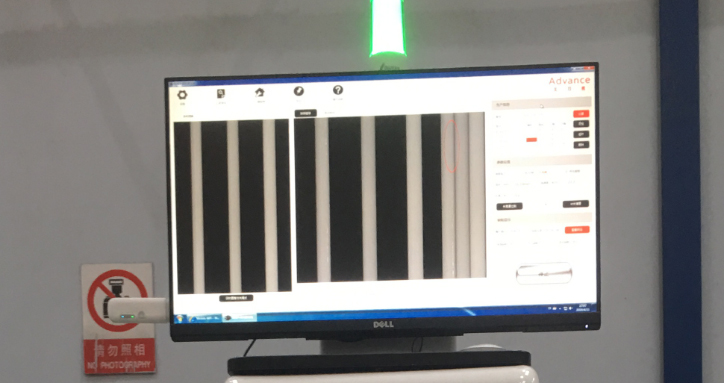

CCD系统软件管理与数据分析平台Ⅴ/Data analysis platform

(1)、线缆缺陷报警次数统计功能

Function of gathering statistics about alarms quantity of wire cable defects

(2)、线缆印刷质量报警次数统计功能

Function of gathering statistics about alarms quantity of letter quality of wire cable

(3)、线缆报警缺陷输出警报功能

Function of alarm of outputting alarm defects of wire cable

(4)、线缆印刷质量输出报警功能

Function of alarm of outputting wire cable letter quality

(5)、线缆质量输出图形界面功能

Function of graphical interfaces for output of wire cable quality

(6)、线缆数据支持二次开发功能

Function of wire cable data supporting redevelopment

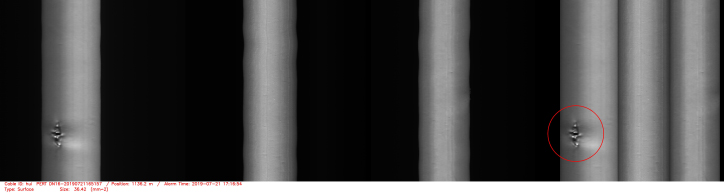

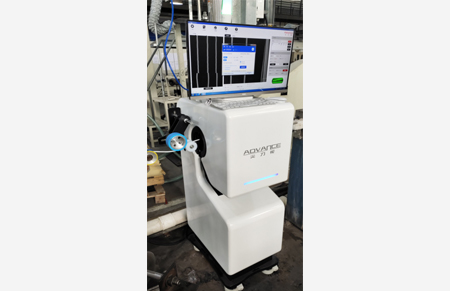

实力展示/Strength shows

线缆表面缺陷检测仪能够采集显示和分析产品表面每一平方毫米的工具。分析内容包括:电缆护套管道管件棒材和水溶胶带表面这是目前检测表面缺陷的方法表面缺陷检测器记录缺陷位置以及保存缺陷图片。操作员可以通过使用表面缺陷检测器来查看当前表面图片,最近一次的表面缺陷图片以及缺陷尺寸。工程和生产监督人员还可以通过表面缺陷检测器来检查缺陷,而无需去查看缺陷本身,并且根据生产批号,导出报表使用尖刀视智能科技表面缺陷检测器,您可确保发送给您客户的产品符合高标准要求,提高产品质量。

Wire cable surface detector is the only tool that is able to collect, display and analyze each square millimeter on the surface of product. The analyzed content covers: surface of cable sheath, conduit, pipe fittings, rod and hydrosoluble adhesive tape. This is the most thorough approach to detection of surface defects at present. The surface defect detector records defect position and stores defects picture. The operator can see picture of current surface, latest surface defect picture and defect size by surface defect detector. The engineering and manufacturing supervision personnel can further detect defects by dint of surface defect detector without need to check the defect itself, and can export report according to manufacturing batch number. Advance intelligent scientific surface defect detector enables you to guarantee the products delivered to customers meet high standard and improve the quality of products accurately and efficiently.

主要性能/The main performance

检测电线、电缆护套、金属管、裸线、尼龙、胶带上的小孔膨胀凹凸表面污点

Detect pinhole bulging, unevenness, surface stain on wire, cable sheath, metallic conduit, bare wire, nylon and adhesive tape

支持线速度高达400米/分钟;

The linear velocity supported is up to 400 meters/minute

根据所需覆盖范围和缺陷尺寸要求,可配置两个三个或四个摄像头;

2,3 or 4 cameras can be configured according to the required coverage and minimal defect size.

在发现任何缺陷的同时,警告操作员或其它生产设备;

Warn operator or other production unit when finding any defects.

记录所有缺陷,用于质量保证记录或用于操作员确认;

Record all defects to be used for quality assurance record or confirmation by operator

保存每个缺陷的位置信息,以便操作员轻易找到这些缺陷;

Store the position information of each defect to enable the operator to spot these defects with ease.

软件分析产品整个360度圆周以及保证轴向覆盖率;

Analyze the product's whole 360°circle with software and guarantee axial coverage.

图1 程序界面

Figure 1 Interface of program

图2 缺陷检测图

Figure 2 Defect detection figure

参数表/Parameter table

最髙线速度 Highest linear velocity | 400米/分钟,1300英尺/分钟 400m/min,1300ft/min |

特征尺寸 Characteristic dimension | 0.3毫米,1毫米,5毫米;0.012英寸,0.040英寸,0.200英寸(根据线速度和线缆直径而定) 0.3mm, 1mm, 5mm and 0.012 inch, 0.040 inch, 0.200 inch (depending on linear velocity and diameter of wire cable) |

电缆直径范围 Cable diameter scope | 毫米-50毫米;50毫米以上0.020英寸-0.080英寸;0.080英寸-2.0英寸;2.0英寸以上(根据攝像头配置而定) 0.5mm-2mm; 2mm-50mm; above 50mm 0.020in-0.080in; 0.080in-2.0in; above 2.0in (depending on the configuration of camera) |

摄像头配置 Camera configuration | |

4个摄像头 4 cameras | 检测线径50mm以上线缆 ct wire cable with linear diameter of above 50mm |

3个摄像头 3cameras | 检测线径50mm以下线缆 detect wire cable with linear diameter of below 50mm |

2个摄像头 2cameras | 可检测小线径线缆的巨大多数缺陷 Can detect majority of defects of wire cable with small linear diameter |

每平方米像素 Pixel per square meter | -100,用于大线径线缆护套和胶带-500,用于小线径线缆护套和胶带100,000以上,用于金属管棒和板 -100, used for wire cable sheath and adhesive tape with large linear diameter -500, used for wire cable sheath and adhesive tape with small linear diameter above 100,000, used for metallic conduit, rod and board |

可检测的缺陷类型 Detectable defect type | 护套缺陷;小孔;凹凸;膨胀;水溶胶带覆盖;管道?管件和棒材刮痕或其他缺陷 Sheath defect; pinhole; unevenness; bulging; coverage of hydrosoluble adhesive tape; scratch or other defects of conduit, pipe fittings and rod |

相邻图片之间的重叠百分比 Percentage overlap between neighboring pictures | 5% |

图像处理 Image processing | 护套缺陷;小孔;凹凸;膨胀;水溶胶带覆盖;管道?管件和棒材读出增强分析每台相机的每一幅图像,保证在最髙速度下产品覆盖率 Read out, enhance and analyze each image of each camera, guarantee product coverage of at the highest speed |

光源 Illuminant | LED或卤素灯 LED or halide lamp |

安装位置 Installation site | 印字仪之前(线缆上投有打印字符),可特殊选择安装在印字仪和水糟之后 Before character printer (printing characters are projected on wire cable), in special case, can be installed behind character printer and sink. |

电源 Power supply | 100V or 230V,根据选择而定 Depending on selection |

广泛应用于:光缆线缆网线金属线圆管胶管金属管护套尼龙胶辊轴类卷烟等在线光学检测领域

Extensively applied to: on-line optical detection regions such as optical fiber cable, wire cable, netting twine, metal wire, circular pipe, hose, metallic conduit, sheath, nylon, rubber roller axis and cigarette, etc.

| * 联系人: | 请填写您的真实姓名 |

| * 手机号码: | 请填写您的联系电话 |

| 电子邮件: | |

| * 采购意向描述: | |

| 请填写采购的产品数量和产品描述,方便我们进行统一备货。 | |

| 验证码: |

|

| 我要评论: | |

| 内 容: |

(内容最多500个汉字,1000个字符) |

| 验证码: | 看不清?! |

联系尖刀视Contact

电话:021-61848028

传真:021-61918020

Mail: rd@jiandaoshi.com

地址:上海市新骏环路189号

共有-条评论【我要评论】